Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is used to cast such materials as metal, glass, and concrete. It is noted for the high quality of the results attainable, particularly for precise control of their metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

Materials

Typical materials that can be cast with this process are iron, steel, stainless steels, glass, and alloys of aluminum, copper and nickel.

Two materials can be cast together by introducing a second material during the process.

Applications

Concrete pipe and form

Typical parts made by this process are pipes, flywheels, cylinder liners, and other parts that are axi-symmetric. It is notably used to cast cylinder liners and sleeve valves for piston engines, parts which could not be reliably manufactured otherwise.

Features of centrifugal casting

- Castings can be made in almost any length, thickness and diameter.

- Different wall thicknesses can be produced from the same size mold.

- Eliminates the need for cores.

- Resistant to atmospheric corrosion, a typical situation with pipes.

- Mechanical properties of centrifugal castings are excellent because of the grain structure formed due to centrifugal action.

- Only cylindrical shapes can be produced with this process.

- Size limits are up to 6 m (20 ft) diameter and 15 m (49 ft) length.

- Wall thickness range from 2.5 to 125 mm (0.098 to 4.921 in).

- Tolerance limit: on the OD can be 2.5 mm (0.098 in) on the ID can be 3.8 mm (0.15 in).

- Surface finish ranges from 2.5 to 12.5 mm (0.098 to 0.492 in) rms.

Benefits

Cylinders and shapes with rotational symmetry are most commonly cast by this technique. "Tall" castings (in the direction of the settling force acting, usually gravity) are always more difficult than short castings. In the centrifugal casting technique the radius of the rotation, along which the centrifugal force acts, replaces the vertical axis. The casting machine may be rotated to place this in any convenient orientation, relative to gravity's vertical. Horizontal and vertical axis machines are both used, simply to place the casting's longest dimension conveniently horizontal.

Thin-walled cylinders are difficult to cast by other means, but centrifugal casting is particularly suited to them. To the rotation radius, these are effectively shallow flat castings and are thus simple.

Centrifugal casting is also applied to the casting of disk and cylindrical shaped objects such as railway carriage wheels or machine fittings where the grain, flow, and balance are important to the durability and utility of the finished product.

Providing that the shape is relatively constant in radius, noncircular shapes may also be cast.

Process for casting metal

Centrifugal casting

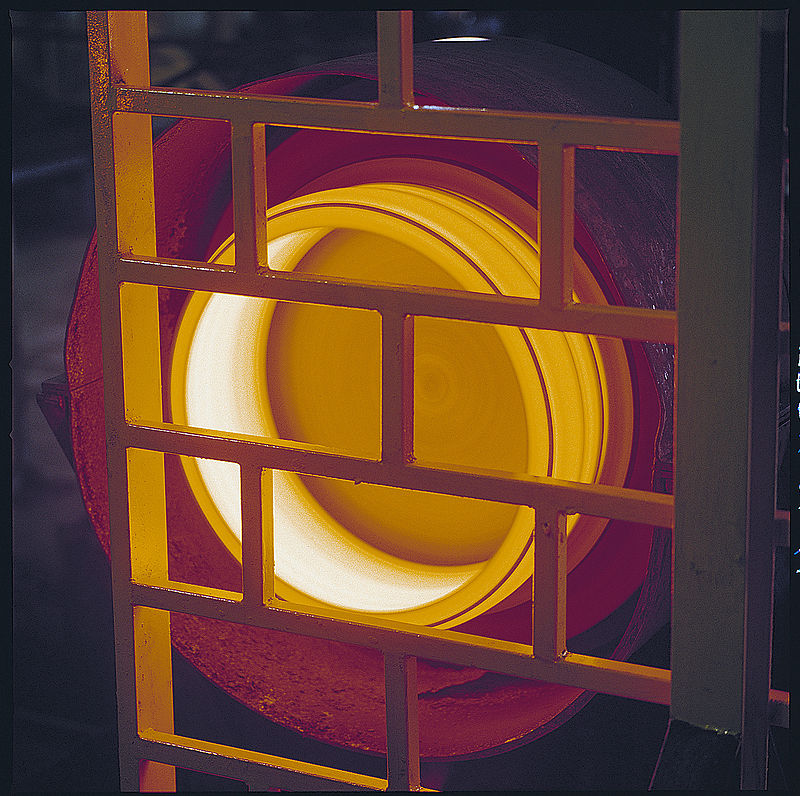

In centrifugal casting, a permanent mold is rotated continuously about its axis at high speeds (300 to 3000 rpm) as the molten metal is poured. The molten metal is centrifugally thrown towards the inside mold wall, where it solidifies after cooling. The casting is usually a fine-grained casting with a very fine-grained outer diameter, owing to chilling against the mold surface. Impurities and inclusions float to the surface of the inside diameter, which can be machined away.

Casting machines may be either horizontal or vertical-axis. Horizontal axis machines are preferred for long, thin cylinders, vertical machines for rings.

Most castings are solidified from the outside first. This may be used to encourage directional solidification of the casting, and thus give useful metallurgical properties to it. Often the inner and outer layers are discarded and only the intermediary columnar zone is used.

Centrifugal casting was the invention of Alfred Krupp, who used it to manufacture railway tires (cast steel tyres for railway wheels) in 1852.

Source: wikipedia.org