Amazon has developed a new warehouse robot that uses touch to rummage around shelves to find the right product to ship to customers.

The robot, called Vulcan, is a meaningful step toward making robots less sausage-fingered compared to human beings. Honing robots’ tactile abilities further may allow them to take on more fulfillment and manufacturing work in the years ahead. Built on advances in robotics, engineering, and physical AI, Vulcan is making our workers’ jobs easier and safer while moving orders more efficiently.

Aaron Parness, Amazon’s director of robotics AI who led the development of Vulcan, explains that touch sensing helps the robot push items around on a shelf and identify what it’s after. “When you’re trying to stow [or pick] items in one of these pods, you can't really do that task without making contact with the other items,” he says.

What many humans do so easily, few robots can tackle. For all their accomplishments—defeating chess masters, driving around city streets, pulling entire kennels’ worth of dog hair out of carpets—most robots are unfeeling, and not just in the emotional sense.

The typical robot is “numb and dumb,” says Aaron Parness, Amazon director, applied science, especially those that work in commercial settings. “In the past, when industrial robots have unexpected contact, they either emergency stop or smash through that contact. They often don’t even know they have hit something because they cannot sense it.”

At their Delivering the Future event in Dortmund, Germany, they are introducing a robot that is neither numb nor dumb. Built on key advances in robotics, engineering, and physical AI, Vulcan is Amazon's first robot with a sense of touch.

Introducing Vulcan: Amazon's first robot with a sense of touch

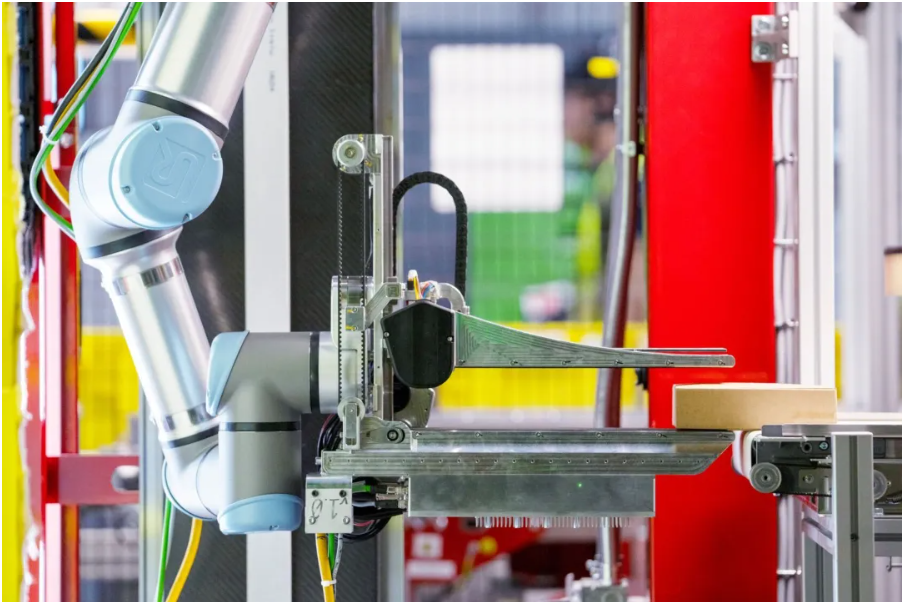

The Vulcan system consists of a conventional robotic arm with a custom spatula-like appendage for poking into a shelf and a sucker for grabbing items to pull them out.

Vulcan has sensors on several of its joints that allow the robot to detect the edges and contours of items. Parness says that machine learning is key to making sense of the sensor signals and also forms part of the algorithmic loop that controls how a robot takes actions. “The special sauce we have is the software interpretation of the force torque and how we wrap those into our control loop and into our motion plans,” he says.

The new robots will work on the same line as human pickers and will aim to spare them from back-aching work by grasping more items from shelves that are high up or down low. Items that the robot decides it cannot find will be reassigned to human workers.

Parness says he does not foresee robots taking on all of the work done inside Amazon’s fulfillment centers. “We don't really believe in 100 percent automation, or lights out fulfillment,” he says. “We can get to 75 percent and have robots working alongside our employees, and the sum would be greater” than either working alone.

Increased use of robots may raise concerns around automation eliminating human jobs. Some economic studies show that robots can eliminate jobs, while others point to a more complex picture, with automation both replacing workers and creating new roles as productivity increases. Amazon’s robot rollout has seen some new jobs created including ones that involve assisting robots when they get confused or stuck.

"Vulcan represents a fundamental leap forward in robotics," Parness says. "It's not just seeing the world, it's feeling it, enabling capabilities that were impossible for Amazon robots until now."

“Working alongside Vulcan, we can pick and stow with greater ease,” says Kari Freitas Hardy, a front-line employee at GEG1, a fulfillment center in Spokane, Washington. “It’s great to see how many of my co-workers have gained new job skills and taken on more technical roles, like I did, once they started working closer with the technology at our sites.”

Sources: aboutamazon.com; wired.com