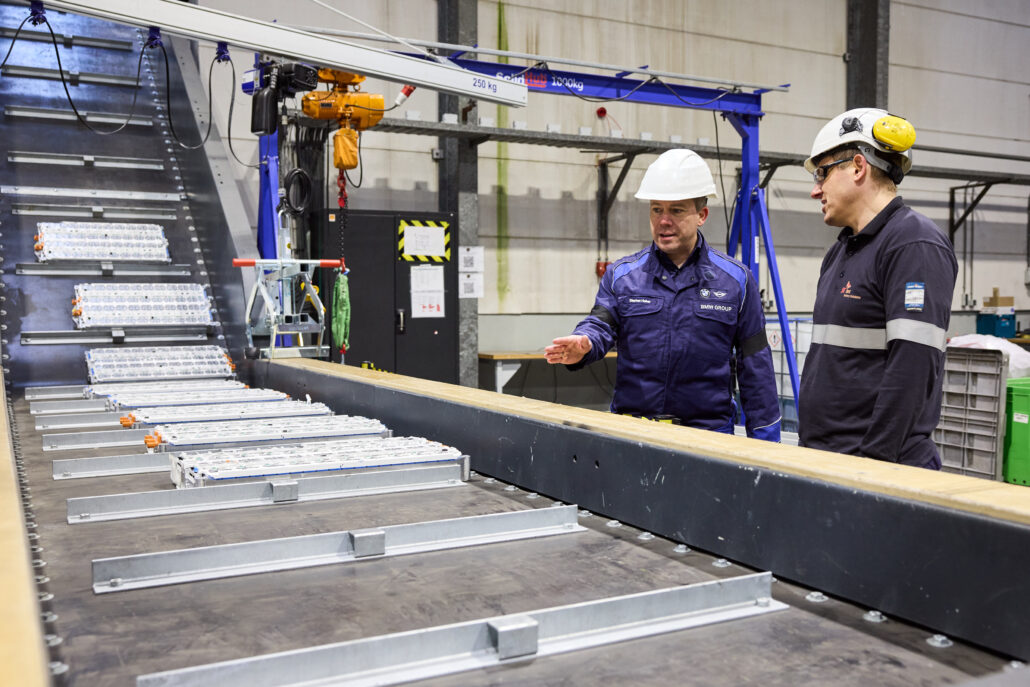

BMW Group has entered into a new European partnership for the recycling of high-voltage batteries. BMW has been working with “SK tes” since November 2024 to recover valuable raw materials such as nickel, cobalt, and lithium from used batteries. The company, which is part of the South Korean environmental and energy group SK, is a provider of resource recovery technologies. The goal is to bring waste batteries from Europe into a closed cycle and to use their secondary raw materials for the production of new batteries. This closed loop system is planned to be extended to North America by 2026.

Circular economy

The BMW Group follows the principles of Re:Think, Re:Duce, Re:Use, and Re:Cycle in the sense of a conservation of resources when it comes to circular economy. From vehicle design and production to recycling and reuse: everything is geared towards ensuring BMW vehicles become a raw materials source for new cars once they reach the end of their useful life. One such example is the BMW Group’s Recycling and Dismantling Centre. Over a period of 30 years now, the centre has developed processes and put them into practice, making key progress in parts and materials recycling.

"Partnerships like this increase our efficiency in terms of the circular economy. In the closed-loop process, all partners mutually benefit from their experiences," says Jörg Lederbauer, Vice President Circular Economy, Spare Parts Supply High Voltage Battery and Electric Powertrain at BMW AG.

Nickel, lithium and cobalt for BMWʼs “GEN 6”

As part of the collaboration, used high-voltage batteries from the BMWʼs development, production, and markets in Europe will be delivered to “SK tes” where they are first mechanically shredded to concentrate the metals in the black mass, followed by chemical processing to recover raw materials such as nickel, lithium, and cobalt. These metals are intended for use in the upcoming BMW GEN 6 powertrain generation. According to the company, the knowledge gained from the recycling process will directly flow into the development departments in order to make future batteries more efficient and sustainable.

Source: press.bmwgroup.com