Rotational Molding (BrE moulding) involves a heated hollow mold which is filled with a charge or shot weight of material.

Resources

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum.

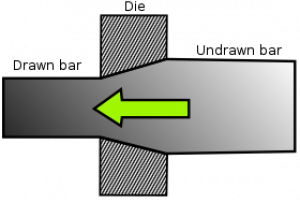

Drawing is a metalworking process which uses tensile forces to stretch metal. As the metal is drawn (pulled), it stretches thinner, into a desired shape and thickness.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. The tool's axes of movement may be literally a straight line, or they may be along some set of curves or angles, but they are essentially linear (in the non mathematical sense).

Threading is the process of creating a screw thread. More screw threads are produced each year than any other machine element.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the tail.

Die cutting is the process of using a die to shear webs of low-strength materials, such as rubber, fiber, foil, cloth, paper, corrugated fiberboard, paperboard, plastics, pressure-sensitive adhesive tapes, foam and sheet metal.