BMW and Figure are taking a two-stage approach to deploying humanoid robots. Figure will first identify use cases for its robots for automotive production at BMW. Once the company identifies appropriate use cases, Figure will deploy its robots in stages at BMW’s manufacturing facility in Spartanburg, South Carolina. The Spartanburg plant is BMW’s largest global manufacturing plant.

The automaker is testing how general-purpose robots could improve factory productivity as part of a multi-stage deployment deal.

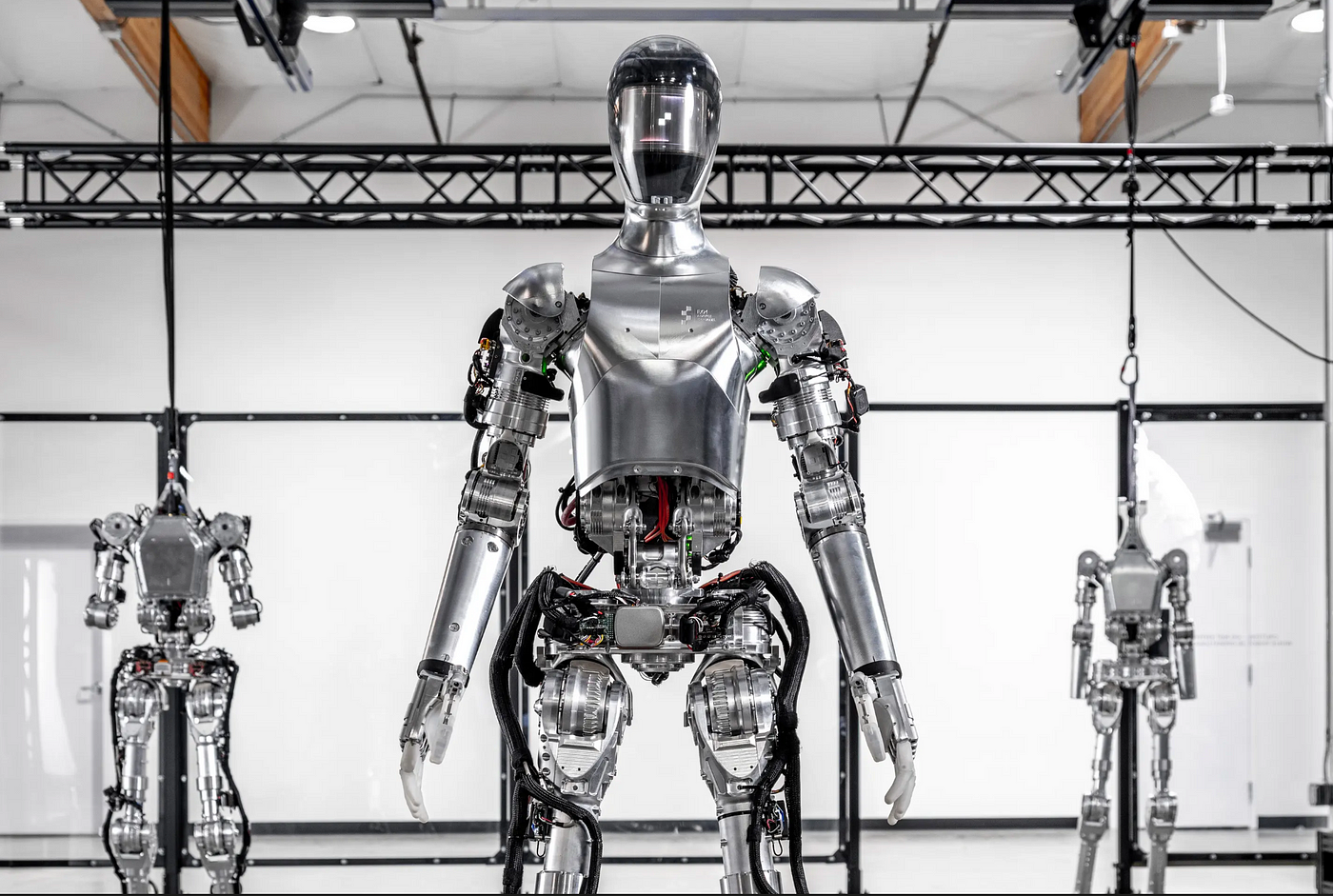

BMW signed a commercial agreement to deploy general-purpose humanoid robots in the automaker’s manufacturing facilities built by Figure, a Silicon Valley-based autonomous robotics company, according to a press earlier this month.

The automaker is assessing the humanoid robot’s ability to perform hazardous, physically demanding or repetitive tasks at its manufacturing plants as part of the milestone-based deployment deal.

BMW and Figure will also explore related technology applications for advanced manufacturing, such as artificial intelligence, robot control, virtualization and robot integration.

Adopting new technology, such as robotics and AI, can help automakers increase efficiency, reduce costs and make production facilities safer for their human workforce.

“The automotive industry, and with it the production of vehicles, is evolving rapidly,” said Robert Engelhorn, president and CEO of BMW Manufacturing, in a statement. “The use of general purpose robot solutions has the potential to make productivity more efficient, to support the growing demands of our consumers, and to enable our team to focus on the transformation ahead of us.”

“Single-purpose robotics have saturated the commercial market for decades, but the potential of general purpose robotics is completely untapped. Figure’s robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment,” said Brett Adcock, founder and CEO of Figure, in a statement.

Several automakers are exploring using robots to increase productivity within their supply chain. GM has worked with its longtime partner Fanuc on robotics solutions to reduce the strain on workers and improve efficiency at its vehicle assembly plants. Meanwhile, Tesla is considering deploying its AI-powered, humanoid “Tesla Bot” within its factories, according to Reuters.

Figure is also working to deploy humanoid robots across other industries, saying its robots can help address labor shortages and perform labor tasks that are undesirable or unsafe for humans.

Source: automotivedive.com