Mercedes AMG High Performance Powertrains (HPP), a 100 % subsidiary of Mercedes-Benz Group specialising in industry-leading Formula 1 technologies, and the Mercedes Benz Center of Competence for Battery Systems designed and developed a completely new and innovative battery system. In addition to its prowess on the racetrack, HPP is capable of rapidly transferring F1 technologies and know-how into high-performance automotive projects. Mercedes-Benz engineers from the road and racetrack and Factorial cell engineers have worked together on delivering an all-new solid-state battery test program, which has brought the first car powered by a lithium-metal solid-state battery to the road.

The prototype solid-state battery was integrated into an EQS at the end of 2024, after intensive testing on various test benches. The all-electric car from Mercedes Benz was slightly modified to fit the solid-state battery and was equipped with all accessories to operate it. The first laboratory vehicle tests were already conducted in Stuttgart at the end of 2024 to prepare for the road tests that started in February 2025.

Solid-state batteries are a promising technology in electric mobility. They use a solid electrolyte instead of a liquid one, which enhances cell safety and allows for the use of new anodes like lithium metal, thus significantly outperforming conventional lithium-ion cells. They also enable next-level energy densities, in combination with a lithium-metal anode. The solid-state technology has the potential to increase the gravimetric energy density for vehicle batteries up to 450 Wh/kg at the cell level and thereby increasing the driving range. Gravimetric energy density refers to the amount of energy stored in a battery cell per unit mass. This metric is crucial for evaluating the efficiency and performance of battery cells, especially in applications where weight is a critical factor, such as in electric vehicles. Solid-state battery technology reduces the battery weight while improving cell safety.

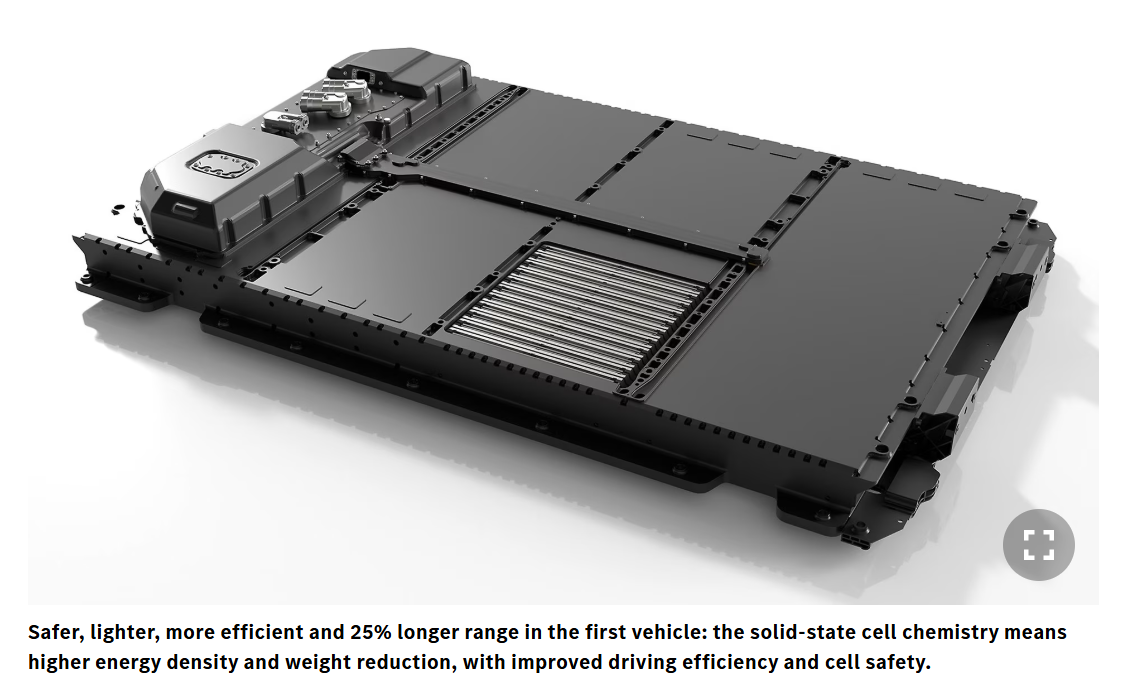

The solid-state battery in the EQS-based vehicle allows for up to 25 % more driving range compared to the same battery weight and size of a corresponding standard EQS battery. Further weight and energy efficiency is achieved through passive battery cooling. The development vehicle is expected to have a range of over 1,000 km (620 miles). For comparison: with a battery capacity of 118 kWh, the current EQS 450+ (energy consumption combined: 19.9–16.3 kWh/100 km | CO₂ emissions combined: 0 g/km | CO₂ class: A)* already offers a range of over 800 km (497 miles).

‘Developing an automotive-scale solid-state battery underlines our commitment to innovation and sustainability. We’re therefore excited to announce that we’ve started road testing with a prototype vehicle equipped with this advanced technology. We will gain crucial insights into possible series integration of this cutting-edge battery technology.’ Markus Schäfer, Member of the Board of Management of Mercedes‑Benz Group AG. Chief Technology Officer, Development & Procurement

‘Being the first to successfully integrate lithium metal solid-state batteries into a production vehicle platform marks a historic achievement in electric mobility. This breakthrough demonstrates that solid-state battery technology has moved beyond the laboratory and into real-world application, setting a new benchmark for the entire automotive industry. Our collaboration with Mercedes-Benz proves that the future of electric vehicles is not just a vision, but a reality we're delivering today.’ Siyu Huang, CEO and Co-Founder of Factorial Energy.

Source: group.mercedes-benz.com