Samsung Electronics has announced it has published a joint research paper titled “Nano-Engineered Thin-Film Thermoelectric Materials Enable Practical Solid-State Refrigeration” with the Johns Hopkins Applied Physics Laboratory (APL). The paper details the development of a next-generation Peltier cooling technology.

Peltier devices achieve cooling via the Peltier effect, in which applying an electric current to a semiconductor causes one side to cool and the other to heat. As it requires no refrigerants, this method is gaining traction as a next-generation alternative to refrigerants that offers a lower-impact solution.

Demonstration of World’s First High-Performance Peltier Refrigerator Opens the Door to Commercialization

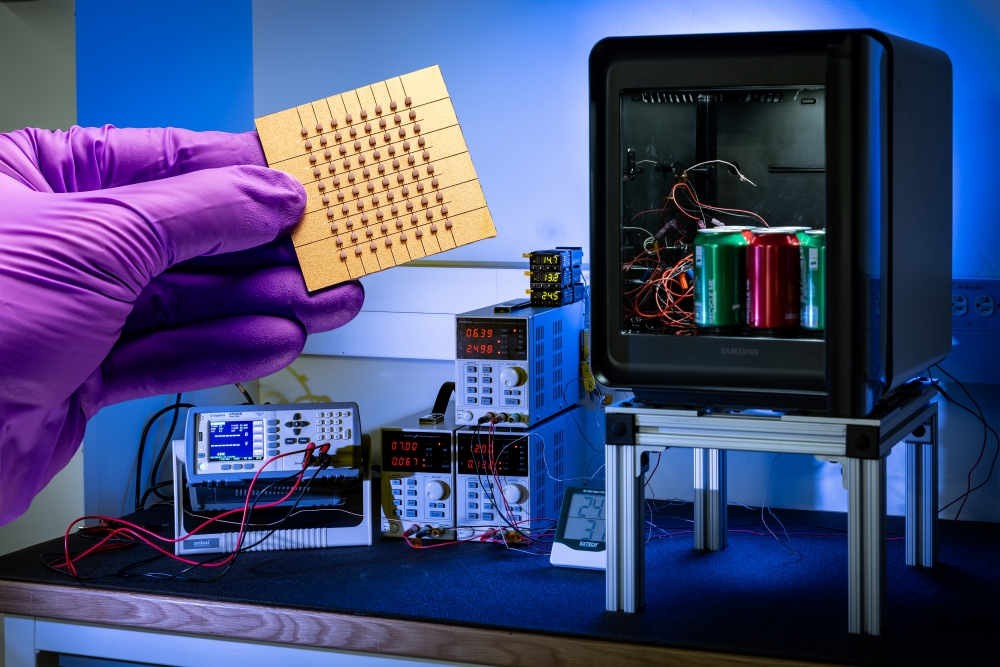

By leveraging newly created thin-film Peltier semiconductor devices advanced through cutting-edge nano-engineering technology for the first time, the research team has successfully developed and demonstrated a high-performance Peltier refrigerator.

This thin-film Peltier refrigerator surpasses the cooling efficiency of traditional vapor compression refrigerators, creating the potential for the commercialization of next-generation refrigerators without refrigerants.

Compared to traditional vapor compression methods, Peltier cooling enables fast and precise temperature control with a simpler configuration, making it applicable to various industrial fields, including home appliances, semiconductors, medical devices, automotive electronics and data centers.

Nanofabrication Boosts Cooling and Resource Efficiency, Paving the Way for Solutions with Reduced Environmental Impact

Achieving superior cooling efficiency in Peltier semiconductor devices is essential for the commercialization of high-performance Peltier cooling.

Samsung and the APL research team have done this by improving the efficiency of Peltier devices by nearly 75% through the use of new thin-film semiconductor materials as well as miniaturization and lightweight design.

The research team confirmed that the new manufacturing process not only drastically reduced the amount of Peltier materials required down to about 1/1,000 of the material typically required, but also simplified the production steps. The newly developed Peltier device demonstrated significant advantages in terms of resource efficiency and mass production. This advancement enhanced scalability and enabled mass production, with promising prospects for significant gains in both cost-effectiveness and environmental impact.

Source: news.samsung.com