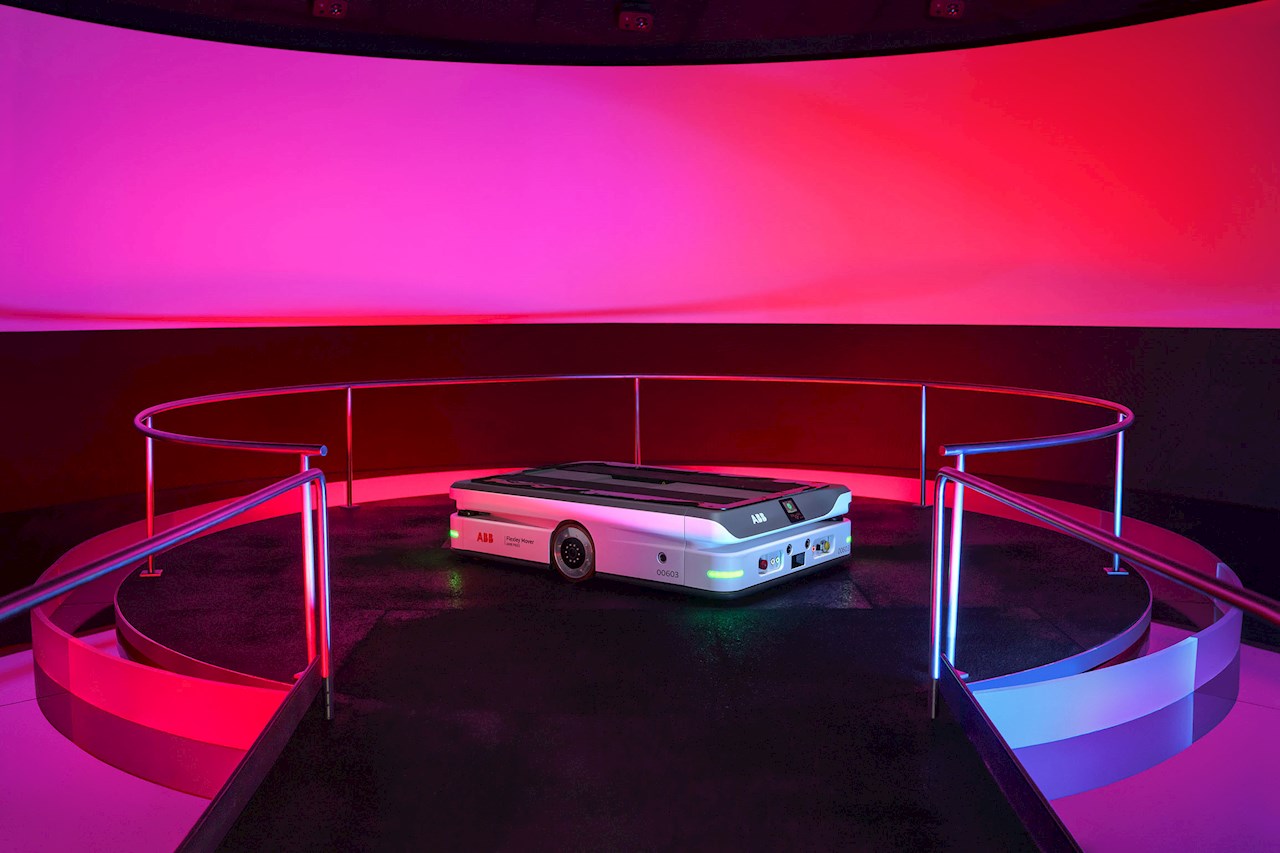

ABB has launched Flexley Mover® P603 platform AMR, the most compact model in its class to handle payloads of up to 1500 kg. Designed to boost intralogistics efficiency, the P603 combines compact design with AI-driven Visual SLAM navigation with the latest version of AMR Studio® software, that maximizes flexibility by enabling different modules to be integrated into the AMR.

The AMR P603 represents a new generation in ABB’s Autonomous Versatile Robotics lineup, designed for effortless real-time task switching. Powered by AI-driven Visual SLAM navigation, it delivers enhanced speed, intelligence, and safety—fully compliant with ISO 3691-4 and ANSI 56.5 standards. With exceptional agility and a positioning accuracy of ±5 mm, it operates without the need for reflectors or infrastructure modifications. Its differential bidirectional drive system ensures smooth navigation in confined production and warehouse environments, while integrated load detection enhances transport stability and safety.

With its compact form and exceptional agility, the P603 is perfectly suited for intralogistics tasks such as end-of-line handling, goods-to-robot workflows, line supply, inter-process transfers, and kitting. It accommodates a diverse range of load types and sizes—including open and closed pallets, containers, racks, and trolleys—all managed by a single AMR thanks to its adaptable top module configuration.

Engineered for modularity, the AMR P603 can be easily customized with a variety of top modules to accommodate different load types. When paired with the AMR Studio® upgrade, it offers fast deployment and effortless customization through drag-and-drop tools, empowering system integrators and end users to create and adjust applications without coding. Features like intuitive no-code mission programming help reduce commissioning time by up to 20%. Additionally, ABB’s integrated Fleet Manager software enables real-time coordination of multiple AMRs across expansive, dynamic production environments.

Smart navigation, compact footprint

Driven by AI-enhanced Visual SLAM, the P603 navigates autonomously through dynamic industrial environments without the need for physical guides or markers. Its advanced suspension system reduces floor quality requirements, making it suitable for both smooth and uneven surfaces. Integrated Center of Gravity-based load sensing further improves stability and operational efficiency. With a top speed of 2 m/s and the ability to run continuously 24/7, the P603 is up to 10% faster than typical SLAM-based AMRs.

ABB remains committed to advancing the fusion of precision robotics, AI, and software to unlock greater autonomy and flexibility in industrial automation.

"Our Autonomous Mobile Robots combine 3D vision with autonomous path planning to give our customers an unprecedented offering: robots that see, sense, and think,” said Marc Segura, President, ABB Robotics. “Our leap in technology brings new levels of intelligence, adaptability, and ease of use to intralogistics. For manufacturers, automakers, and logistics providers, it enables safer, smarter workflows with minimal complexity, enabling transformation with immediate impact."

Source: new.abb.com/news