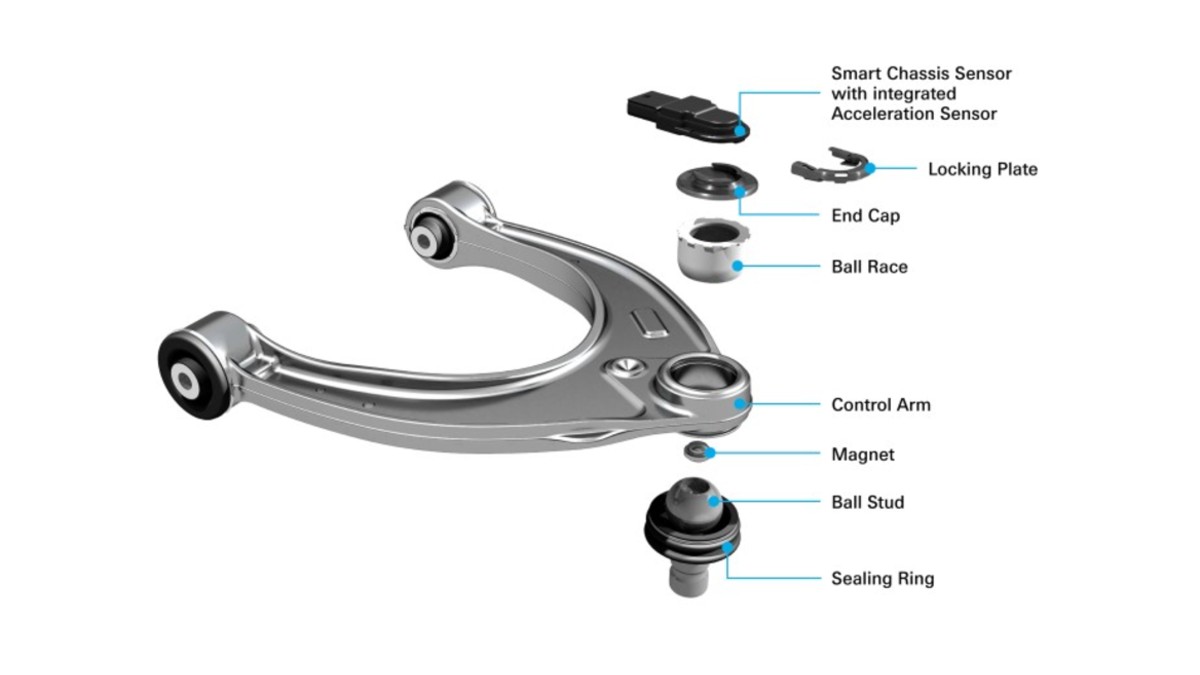

ZF is introducing the next generation of this intelligent chassis technology, just months after the launch of its Smart Chassis Sensor. The latest version now includes an integrated accelerometer in its advanced configuration, enabling direct data collection from within the ball joint. In addition to measuring wheel height, the enhanced sensor can now capture three-dimensional acceleration data.

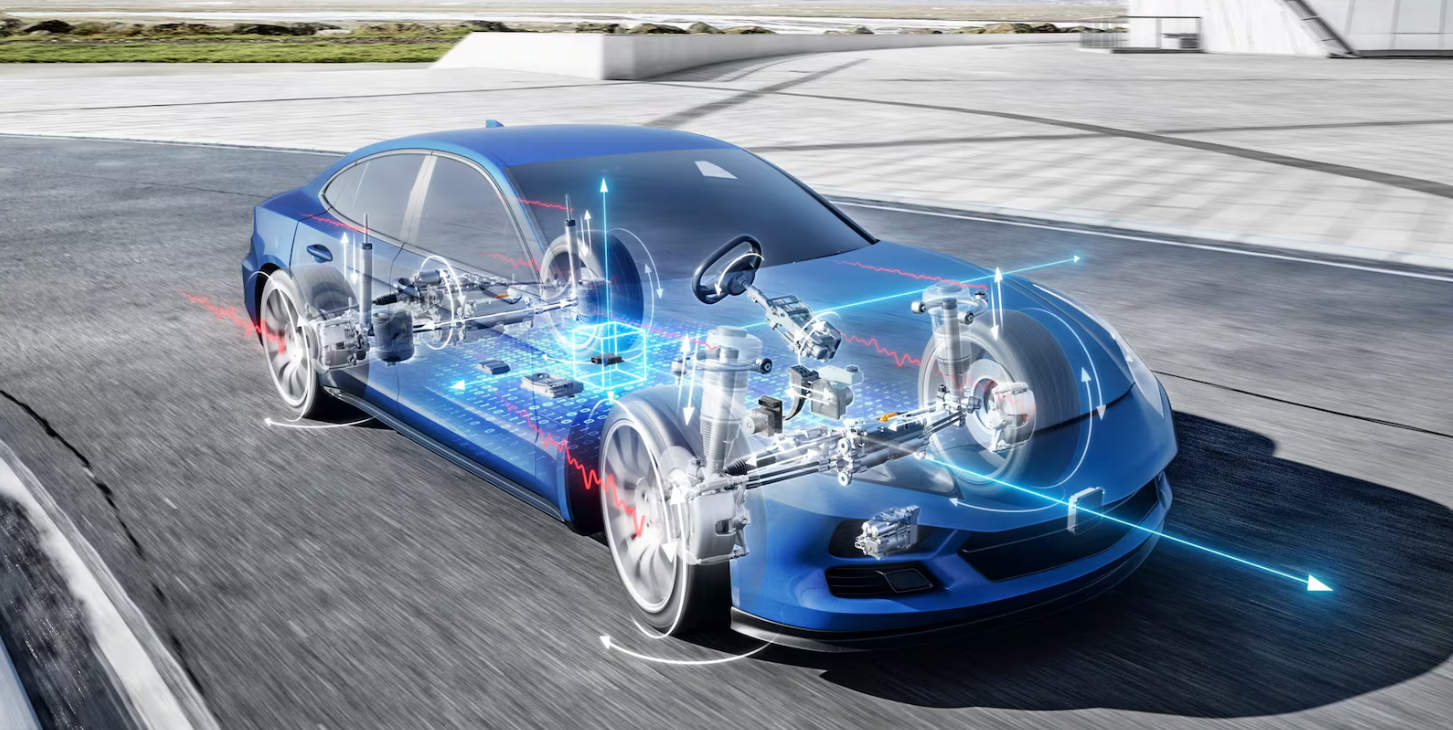

As automotive trends such as electrification, software-defined vehicles, and automated driving continue to evolve, the chassis has become a strategic cornerstone in modern vehicle architecture. In response, ZF is rolling out a significant update to its Chassis 2.0 strategy - an approach that integrates smart components, by-wire systems, and digital platforms to support more connected and efficient mobility.

Chassis 2.0: Integrated Technology and Advanced, System-Ready Components

ZF is scaling up the production of steer-by-wire and brake-by-wire technologies, replacing traditional mechanical linkages with electronic systems that enable new levels of vehicle control. A major milestone in this effort is the series production of the NIO ET9, which features ZF’s fully electronic steering system. ZF has also secured contracts with two additional Chinese automakers and Mercedes-Benz, with the latter planning to implement the technology starting in 2026.

Beyond steering and braking, ZF continues to lead in the damping segment. Its semi-active Continuous Damping Control (CDC) system and the sMOTION platform have earned it a 40% global market share. In rear-axle steering, ZF’s AKC system commands a dominant 73% share of the global market, reaching up to 80% in Asia.

ZF Expands Software Capabilities for Greater Integration and Efficiency

ZF is further advancing its hardware-agnostic software strategy, strengthening its position as a full-system provider within the automotive components ecosystem. At the heart of this effort is the cubiX platform, which enables dynamic chassis control using components from a variety of manufacturers. This flexibility simplifies system integration and accelerates development timelines.

A key innovation within the platform is cubiX Tuner, a tool that automates the adaptation of control units to each manufacturer’s specific parameters. This significantly streamlines the calibration process.

“This directly responds to a key demand from customers across all regions—especially in Asia: to speed up development and reduce costs,” said Philippe Gasnier, Development Director of ZF’s Chassis Solutions Division.

Another notable feature is load detection. Leveraging a dedicated algorithm, the system can estimate the vehicle’s weight—useful for determining if legal load limits have been exceeded, such as after loading luggage or cargo. This not only ensures regulatory compliance but also helps prevent unexpected roadside complications.

Sensors and Predictive Maintenance: The Next Frontier in Vehicle Monitoring

ZF’s Smart Chassis Sensor, already in production for the Cadillac CELESTIQ, represents a leap forward in real-time chassis condition monitoring. Integrated directly into the ball joint, the sensor captures three-dimensional acceleration data and feeds into the Chassis Health system—ZF’s diagnostic tool for evaluating the mechanical state of the vehicle.

Powered by artificial intelligence, this system enables predictive maintenance, helping to identify potential issues before they cause failures. This innovation has significant implications for OEMs, parts suppliers, and service workshops alike—supporting more efficient maintenance planning and reducing downtime.

"At ZF, we benefit from this trend in two ways," explained Dr. Peter Holdmann, Member of the ZF Board of Management and responsible for Automotive Chassis Technology. "First, because of the expected global increase in demand for system-ready components, such as our steer-by-wire or brake-by-wire solutions. In addition, there is a strong demand for new and compelling features that seamlessly coordinate these components and deliver great benefits to end users."

"The Chassis 2.0 approach responds exactly to the current market requirements," said Dr. Holdmann. "We anticipate that this segment of our portfolio alone will account for approximately 33% of the global market by the end of this decade, generating total revenues of around €4.8 billion. We are poised to establish market and technology leadership positions in all key segments of our Chassis 2.0 portfolio."

Source: aftermarketinternational.com