TLT Manufacturing has unveiled four new production facilities at the High-Tech Hill technology park in Vilnius, Lithuania, marking what it calls a major milestone for strengthening Europe’s manufacturing resilience and safeguarding intellectual property.

The expansion includes a 33,000 m² PCB plant — Europe’s first newly built PCB factory in 20 years — designed for complex multilayer boards, equipped with an in-house innovation lab, and featuring advanced processes such as vertical continuous plating.

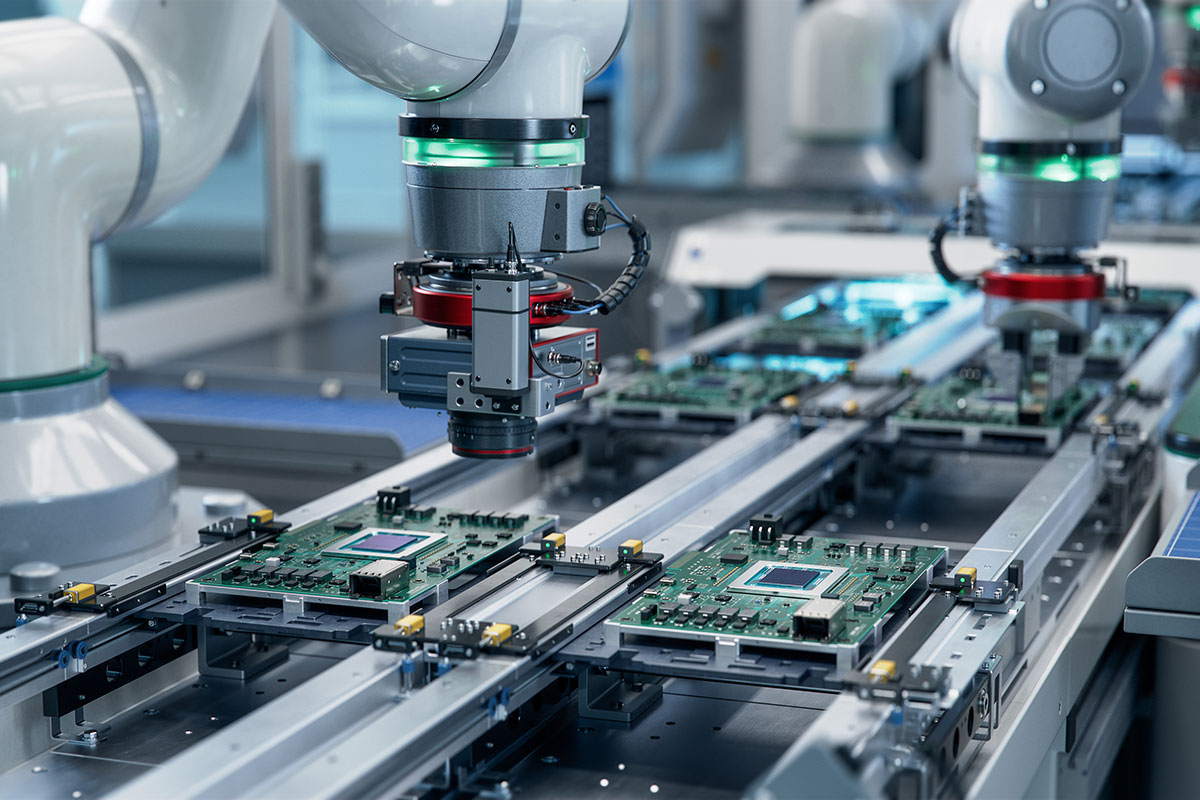

Alongside it, TLT has opened a 22,700 m² electronics assembly facility, spanning prototypes through to high-volume serial production and box-builds. The site is fitted with SMT and THT lines to deliver high-quality, scalable output.

A third plant, covering 22,100 m², focuses on plastics and mechanical components, uniting tooling, moulding, and automation under one roof with broad material flexibility in technical plastics and rubbers. The fourth site is dedicated to component assembly, helping accelerate time-to-market and production scale.

By consolidating PCB manufacturing, electronics assembly, plastics, mechanics, and final product build on a single secure campus, TLT says it offers customers a fully vertically integrated model. Key industries set to benefit include defence, medical, and automotive, with gains in IP protection, supply chain security, and quality assurance.

In total, the €320 million investment adds 82,100 m² of new production space, creating 1,370 jobs and boosting annual output from 10 million to 30 million electronic devices. TLT expects the additional capacity to support its near-term revenue goal of €1.5 billion.

Source: evertiq.com