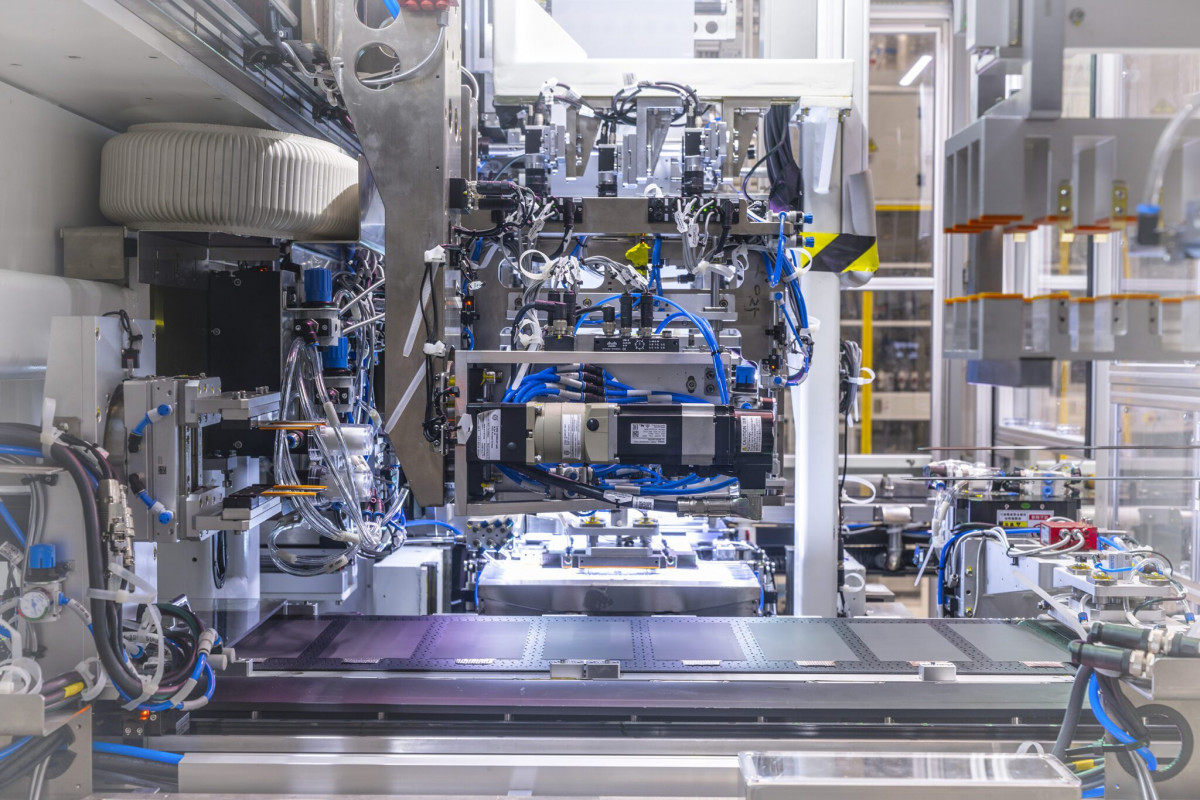

Volkswagen subsidiary PowerCo has officially brought its Salzgitter gigafactory in Germany online, commencing production of its first Unified battery cells manufactured in Europe. According to Volkswagen, this marks the first time the Group has designed, developed, and produced battery cells entirely within Europe.

The newly produced cells will be supplied to Volkswagen Group brands for final road testing, with initial deployment planned for next year in the Electric Urban Car Family, including models from Volkswagen, ŠKODA, and SEAT/CUPRA.

PowerCo is expected to meet around 50% of the Volkswagen Group’s Unified Cell demand, with the remaining volumes sourced from external suppliers. The standardised Unified Cell platform is intended for global use across multiple brands and battery chemistries, including lithium iron phosphate (LFP), nickel-manganese-cobalt (NMC), and potentially solid-state technologies.

The first Unified Cell manufactured in Salzgitter is based on NMC chemistry and delivers approximately 10% higher energy density compared to previous generations. It is designed to work with Volkswagen’s new cell-to-pack battery architecture, aimed at improving vehicle range, efficiency, and overall performance. Further variants, including LFP-based cells, are planned.

Production will be scaled up progressively over the next year. The Salzgitter plant has an initial annual capacity of up to 20 gigawatt-hours (GWh)—enough to supply around 250,000 electric vehicles—and can be expanded to 40 GWh.

Spanning 69,000 square metres, roughly equivalent to ten football pitches, the facility will act as the lead plant for PowerCo’s upcoming gigafactories in Valencia, Spain, and St. Thomas, Canada.

In addition to manufacturing, the Salzgitter site includes a growing research and development centre, with new testing facilities expected to come online in early 2026.

Source: volkswagen-group.com